Polymethacrylates (PMMA, Plexiglas)

Better known as Plexiglass

Polymethyl methacrylate (PMMA), also known as acrylic or plexiglas, is a high volume amorphous, transparent and colorless commodity thermoplastic that can be easily processed and converted into many finished and semi-finished products.

Most commercial grades of PMMA are polymerized by free radical polymerization, yielding atactic polymers whereas anionic polymerization yields syndiotactic or isotactic polymers. Most commercial grades of PMMA, however, are atactic with a glass transition temperature of 398 K (125 °C).

Commercial PMMA is often copolymerized with comonomers other than methyl methacrylate. The Tg of these products can vary, ranging broadly from approximately 360 K to 430 K (87 to 157 °C).

PMMA is known for its stiffness, hardness and excellent weatherability. Unmodified PMMA, however, is rather brittle and has low impact strength and fatigue resistance. To increase its toughness, it is often modified with core-shell rubber or other impact modifers. These resins offer seven to 10 times the impact resistance of standard PMMA while maintaining high transparency.

Because of its high transparency (92% transmission) PMMA can be used as a lightweight and shatter-resistant replacement for regular glass. It has sufficient impact resistance to be machined and is often an economical alternative to polycarbonate (PC) when very high toughness and impact strength is not required. It comes in a variety of forms such as sheets, rods, and tubes, and is used for signs, optical fibers, architectural structures, tail lights for cars, bathtubs and sanitary fixtures, to name only a few applications.

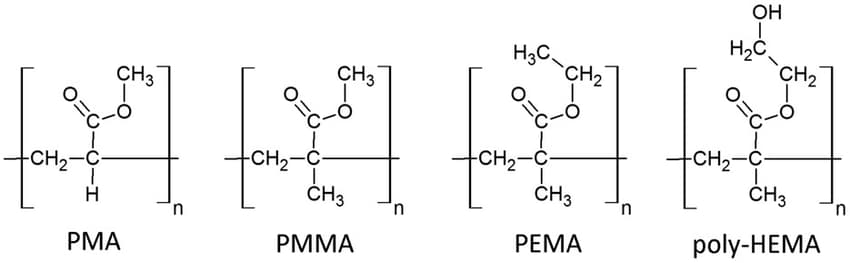

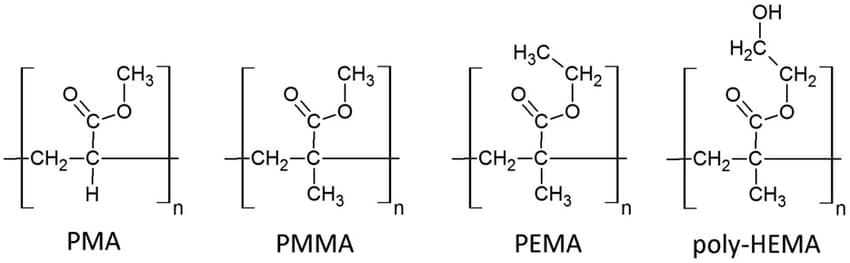

Many other methacrylic monomers are commercially available. They are either copolymerized with methyl methacrylate to improve its properties or are added to many other resin systems to make a wide range of polymer-based products like binders in paints, coatings, toners, inks, and water-soluble polymers.

Most commercial grades of PMMA are polymerized by free radical polymerization, yielding atactic polymers whereas anionic polymerization yields syndiotactic or isotactic polymers. Most commercial grades of PMMA, however, are atactic with a glass transition temperature of 398 K (125 °C).

Commercial PMMA is often copolymerized with comonomers other than methyl methacrylate. The Tg of these products can vary, ranging broadly from approximately 360 K to 430 K (87 to 157 °C).

PMMA is known for its stiffness, hardness and excellent weatherability. Unmodified PMMA, however, is rather brittle and has low impact strength and fatigue resistance. To increase its toughness, it is often modified with core-shell rubber or other impact modifers. These resins offer seven to 10 times the impact resistance of standard PMMA while maintaining high transparency.

Because of its high transparency (92% transmission) PMMA can be used as a lightweight and shatter-resistant replacement for regular glass. It has sufficient impact resistance to be machined and is often an economical alternative to polycarbonate (PC) when very high toughness and impact strength is not required. It comes in a variety of forms such as sheets, rods, and tubes, and is used for signs, optical fibers, architectural structures, tail lights for cars, bathtubs and sanitary fixtures, to name only a few applications.

Many other methacrylic monomers are commercially available. They are either copolymerized with methyl methacrylate to improve its properties or are added to many other resin systems to make a wide range of polymer-based products like binders in paints, coatings, toners, inks, and water-soluble polymers.

Applications in the exhibition and advertising sector

Displays for shop windows of all types of shops: phone shops, jewelers, shoe shops, wedding lists, opticians and gift items. Brochure holder, menu holder, business card holder, catalog holder, flyer holder. Accessories for slatted panels, glasses holders, price holders, shoe racks, shelves for slatted panels in plexiglass for optical stores, clothing and footwear stores. Bar and buffet accessories, Plexiglas food displays for the presentation and distribution of food in catering, collective catering, bars and in the hotel sector. Plexiglass displays and containers for hospitality products for hotels, guesthouses, resorts and B & Bs. Displays for technical items & industrial products, Plexiglas displays for trade fairs and shops for industrial products: valves, small engines, tools, small metal parts, pressure gauges, pipes, heating and plumbing and spare parts. Plexiglass photo frames of different shapes and sizes, Household items, Bathroom accessories and kitchen accessories in plastic material, Hob cover displays and much more ..

Related News

Diemme Display srl

sede operativa: via Staffora 8

sede legale: via Leopardi 2

20090 Opera (MI)

p.iva 08540780965

sede operativa: via Staffora 8

sede legale: via Leopardi 2

20090 Opera (MI)

p.iva 08540780965

ph: +39+390257602068

e-mail: info@diemmedisplay.it

Send us a message:

^